Coffee seeds are generally planted in large beds in shaded nurseries. The seedlings will be watered frequently and shaded from bright sunlight until they are hearty enough to be permanently planted. Planting often takes place during the wet season, so that the soil remains moist while the roots become firmly established.

There is typically one major harvest a year. The crop is picked by hand and all of the cherries are stripped off of the branch at one time. Only the ripe cherries are harvested, and they are picked individually by hand. Pickers rotate among the trees every eight to 10 days, choosing only the cherries which are at the peak of ripeness.

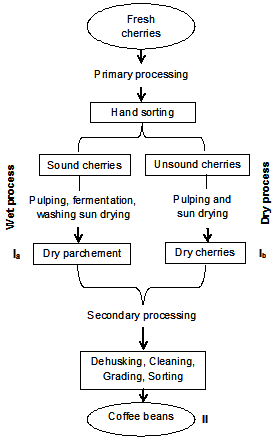

We use the Dry Method which is the age-old method of processing coffee. The freshly picked cherries are simply spread out on huge surfaces to dry in the sun between 5 and 7 days. In order to prevent the cherries from spoiling, they are raked and turned throughout the day, then covered at night or during rain to prevent them from getting wet. Depending on the weather, this process might continue for several days for each batch of coffee until the moisture content of the cherries drops to 12%.

Typically, the bean size is represented on a scale of 10 to 20. The number represents the size of a round hole's diameter in terms of 1/64's of an inch. A number 10 bean would be the approximate size of a hole in a diameter of 10/64 of an inch, and a number 15 bean, 15/64 of an inch.

Finally, defective beans are removed either by hand or by machinery. Beans that are unsatisfactory due to deficiencies (unacceptable size or color, over-fermented beans, insect-damaged, unhulled) are removed. This process is done both by machine and by hand, ensuring that only the finest quality coffee beans are got.

Most roasting machines maintain a temperature of about 550 degrees Fahrenheit. The beans are kept moving throughout the entire process to keep them from burning.

When they reach an internal temperature of about 400 degrees Fahrenheit, they begin to turn brown and the caffeol, a fragrant oil locked inside the beans, begins to emerge. This process called pyrolysis is at the heart of roasting — it produces the flavor and aroma of the coffee we drink.

The length of time the grounds will be in contact with water determines the ideal grade of grind Generally, the finer the grind, the more quickly the coffee should be prepared. That’s why coffee ground for an espresso machine is much finer than coffee brewed in a drip system. We take a moment to examine the beans and smell their aroma — in fact, the scent of coffee alone has been shown to have energizing effects on the brain.

First, the taster — usually called the cupper — evaluates the beans for their overall visual quality. The beans are then roasted in a small laboratory roaster, immediately ground and infused in boiling water with carefully-controlled temperature. The cupper noses the brew to experience its aroma, an essential step in judging the coffee's quality.

After letting the coffee rest for several minutes, the cupper breaks the crust by pushing aside the grounds at the top of the cup. Again, the coffee is nosed before the tasting begins.

To taste the coffee, the cupper slurps a spoonful with a quick inhalation. The objective is to spray the coffee evenly over the cupper's taste buds, and then weigh it on the tongue before spitting it out.

Samples from a variety of batches and different beans are tasted daily. Coffees are not only analyzed to determine their characteristics and flaws, but also for the purpose of blending different beans or creating the proper roast. An expert cupper can taste hundreds of samples of coffee a day and still taste the subtle differences between them.